Home / MMC Asia Japan Restricted Models

Portable Tank Gauging Device Sonic Tape

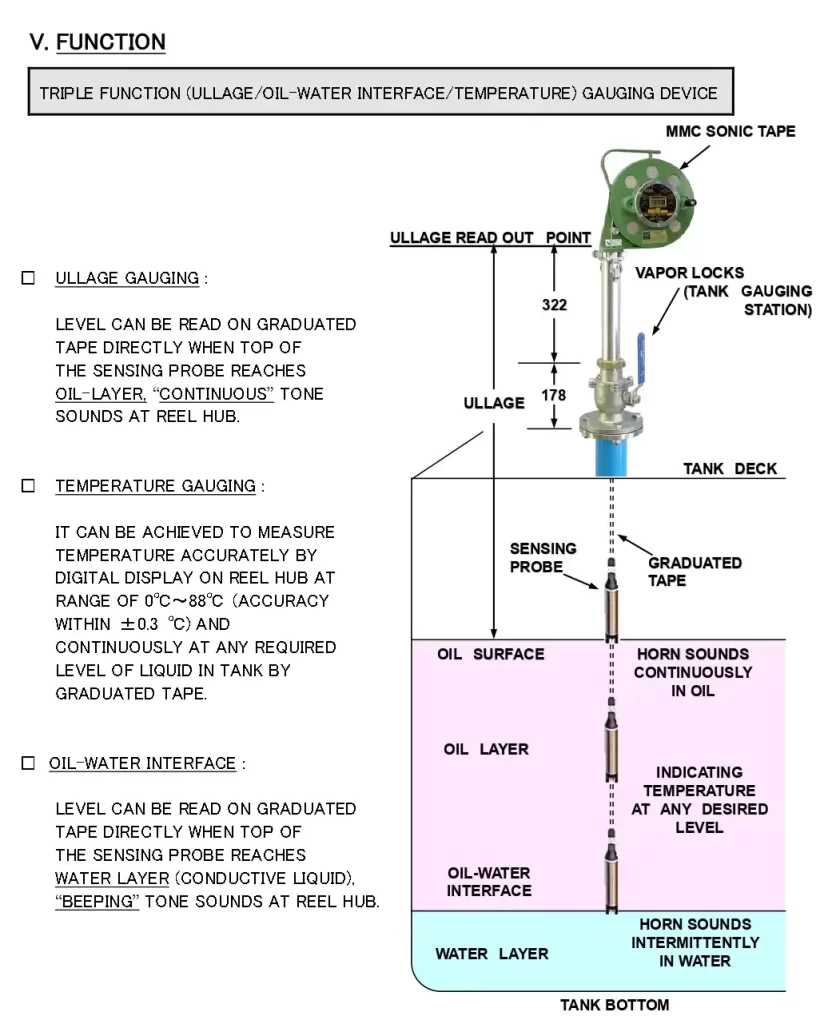

TRIPLE [ULLAGE(U). INTERFACE(I). TEMPERATURE(T)] FUNCTION

Model. “D-2401-2”

In gauging cargo oil volume within a tank, oil levels are determined by measuring with a tank table. However, it’s important to note that oil levels vary with temperature, and crude oil often contains significant water content. This water naturally separates from the oil and settles at the bottom of the tank.

The “Sonic Tape” (a term commonly used by major oil companies) is a portable tank gauging device developed by MMC. It utilizes an ultrasonic sensing probe to detect liquid levels, allowing direct, accurate readings on the tape itself. Unlike conventional gauging methods that use a “sounding steel tape” to identify oil levels based on oil residues on the tape, the Sonic Tape provides high-precision readings without needing to average multiple measurements.

The MMC portable Sonic Tape is designed to work on vapor locks, ensuring compliance with marine safety standards by using restricted devices on deck. This closed system limits vapor emissions and enhances safety during tank gauging. According to the U.S. Coast Guard Marine Safety Center, such restricted devices are compliant with 45 CFR Part 39.30-1(i), as they minimize cargo vapor release into the atmosphere.

This device is intrinsically safe and meets IEC standards (Ex ia IIB T4) for use in explosive gas environments. Its intrinsic safety classification ensures reliable operation within hazardous areas, making it suitable for use in explosive atmospheres commonly found on oil tankers.

Portable Tank Gauging Device Sonic Tape

IMO MARPOL REGULATION 15,(3)(b) 【CONSOLIDATED IN EDITION 2006, ANNEX I, CHAPTER 4, REGULATION 32】requires effective oil-water interface detectors approved by the administration for a rapid and accurate determination of the oil-water interface in slop tanks and it shall be available for use in other tanks where the separationof oil and water iseffected and from which it is intended to discharge effluent direct to the sea.

MMC PORTABLE TRIPLE FUNCTION(ULLAGE / TEMPERATURE / OIL-WATER INTERFACE)GAUGING DEVICE MODEL. “D-2401-2” has been inspected and type-approved by the administration according to the specification mepc.5(xiii) as OIL-WATER INTERFACE DETECTOR and being circulated to imo member.

Specification

| CONSTRUCTION | |

|---|---|

| Tape Length | 15m, 25m, 30m, 35m |

| Weight Of Device | 4.0kg, 4.4kg, 4.6kg, 5.0kg |

| Sotrage Temperature Limits | -20℃ ~ +70℃ |

| POWER SOURCE | |

| Battery | Alkaline Battery Dc 9v |

| Battery Model | Mn1604, 6am6 (6lr61) |

| Battery Life | Approx. 400 Hours |

| Battery Drain | 1.3ma (In Air) 2.6ma (In Fluid) 1.3ma (In Temp. Gauging) 10.0ma (Night Light On) |

| Storage Temperature Limit Of Battery | +10℃ ~ +25℃ |

| ULLAGE (U)/OIL-WATER INTERFACE (I) GAUGING | |

| Accuracy Of Sensing Probe | IUT SENSING PROBE Within ±1mm |

| Minimum Detectable Liquid Level Or Interface Level From Tank Bottom | 10mm |

| Accuracy Of Graduated Tape | 〔error Within Jis. Standard (1st Class) 〕 |

| Operated Temperature Limits Of Sensing Probe | 0℃ ~ +70℃ |

Special Features

1.Direct Gauging

MMC PORTABLE SONIC is constructed with graduated conductive tape adopt jis. (1st class) standardtape, so that the tank liquid LEVEL READ-OUT on the graduated tape directly. it is much more accurate than the conventional presumed sounding to read oil adhered position on tape.

2.Portable Type

- A single portable device is able to be used at all tanks.

- Installation for the vapor lock is symple.it costs less than the fixed type tank gauging equipment.

- Easy carrying to ship’s cabin for check accuracy and function of the device.

- Upon repairs, the portable device can be sent to an mmc service station, therefore attendance fee of the service engineer on board can be saved.[it is recommended to send the portable device to service station since the high-accuracy facility is required for temperature calibration.]

- Portable device can be used as a substitute for the fixed type gauging equipment when malfunction is caused, also portable device can be used for calibrating it

3.Sonic Detection

MMC SONIC TAPE ADOPTS SENSOR with ULTRA-SONIC THEORY. ultra-sonic sensor can detect any liquid with highest response without influenced by high viscosity liquid adhered to sensing probe, such as float type or capacitance type sensor.

4.Closed Or Restricted Construction

“MMC” sonic tape is to be coupled on “MMC” vapor lock (tank gauging station) installed on tank top to avoid releasing dangerous gas from tank as gas-tight or restricted construction,

5.Intrinsically Safe Apparatus

This device is an intrinsically safe apparatus.it can be used in the dangerous flammableatmosphere under the category of ex ia ⅱb t4

6.Oil-water Interface Detector

This device is approved by administration in accordance with marpol 1973/78 annex 1, regulation 15,(3),(b) and specification mepc.5(xⅲ) .as for the oil-water interface detector

7.Facility Of Level Alarm

This device can be used as “level alarm” at any desired level for safe loading. (the area of audible signal from the device on deck depends on the ambient condition. therefore, it must be used under the user’s responsibility.)

8.Tape Wiper

The the tape wiper ass’y is equipped which can clean surface of the graduated tape by hand operation.