Home / MMC Closed Type Sampler Flexi-Dip

Gas Tight Closed Sampling Systems

MMC Closed Type Sampler Flexi-Dip

In a move to address the special needs of chemical and refined product carriers and barges, MMC International Corp. has announced the release of a new “closed” gauging system design.

Featuring an ullage range of 15-35 meters, the system uses a new “PeeK” plastic sensor suitable for most chemical products and also refined petroleum products.

Surface Mount Technology

The sensor employs state-of-the-art SMT (Surface Mount Technology) and circuit enhancements that provide better long term reliability, more precise ullage level sensing, and improved oil-water “layer detection.”

The new compact model retains the same trouble-free, gas-tight, heavy duty mechanical design as its larger VLCC class brother. Both models now have built-in viewing window wipers.

“Intrinsically Safe”

All models are also approved as “Intrinsically Safe” and as Class 1, Div. 1 gas groups’ C&D equipment.

Equipment quality is assured by SIRA (Baseefa) annual audits to confirm that quality requirements of ISO 9001 are maintained in addition to their supplementary requirements.

Periodic safety compliance audits are also conducted by CSA, SIRA (ATEX), BV, DNV, CSS.

MMC is the world’s leading manufacturer of portable instruments for measuring ullage, oil-water interface, temperature, and bottom dryness in shipboard and land-based petroleum and chemical tank systems.

| Specifications: | |

|

Display Readable Temperature Range *Reading Limit Due to 3-1/3 Digit LCD Display on °F Range |

°F = -40° to 199.9°* °C = -40° to 150.0° |

| Guaranteed Temperature Calibration Range |

32°F to 190°F (0°C to 88°C) |

| Accuracy Over Calibration Range | ±0.2°F (±0.1°C) |

| Accuracy Linear Measurements | ±1/8” (±2.0 mm), Plus ±0.1% of Total Tape Length, worst case |

| Minimum Detectable Tank Bottom Liquid Level | 3/8” (10mm) |

| Minimum Detectable Floating Product Level | 1/8” (3mm) |

| Batteries for Intrinsically Safe Operation Only (Supplied) | Duracell MN1604 |

| Battery Drain (Temperature Mode) |

1.3 ma (In Air) 2.6 ma (In Fluid) |

| Display |

3-1/2″ Digit Liquid Crystal Display 1/2” Character Height |

| Operating Temperature Limit of Liquid Crystal Display |

-40°F to 176°F -40°C to 80° |

| Storage Temperature Limits |

-67°F to 185°F -55°C to 85°C |

| Available Tape Length, *Single Face Scales |

50 ft (15 m) 65 ft (20 m) 75 ft (25 m) 100 ft (30 m) *100 ft (10ths & 100ths) 35m |

| Hazardous Environments |

Certified Intrinsically Safe BASEEFA/SIRA, |

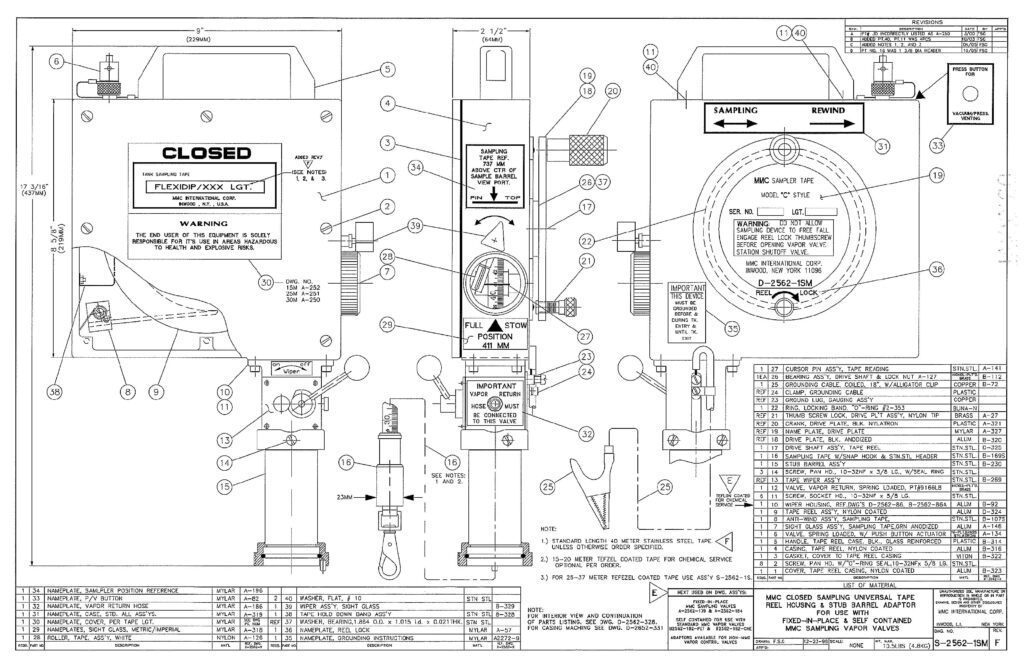

Sampler Tape Model “C” Style

- Fixed-In-Place (FIP)

- Portable-In-Place (PIP)

- Both Flexi-Dip systems

Fixed-in-place And Portable Systems

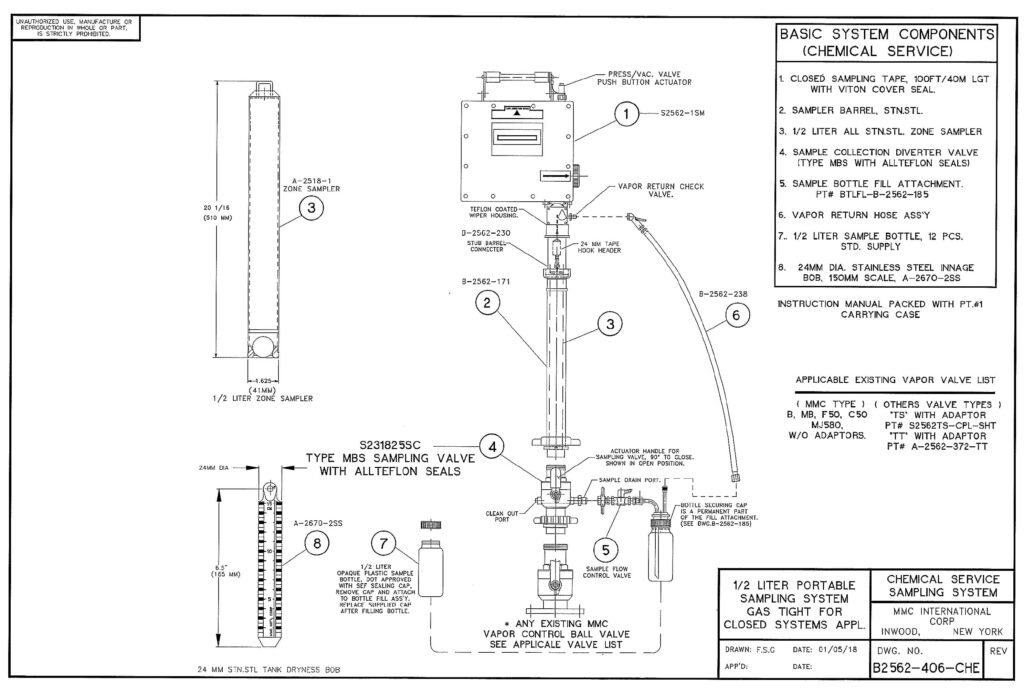

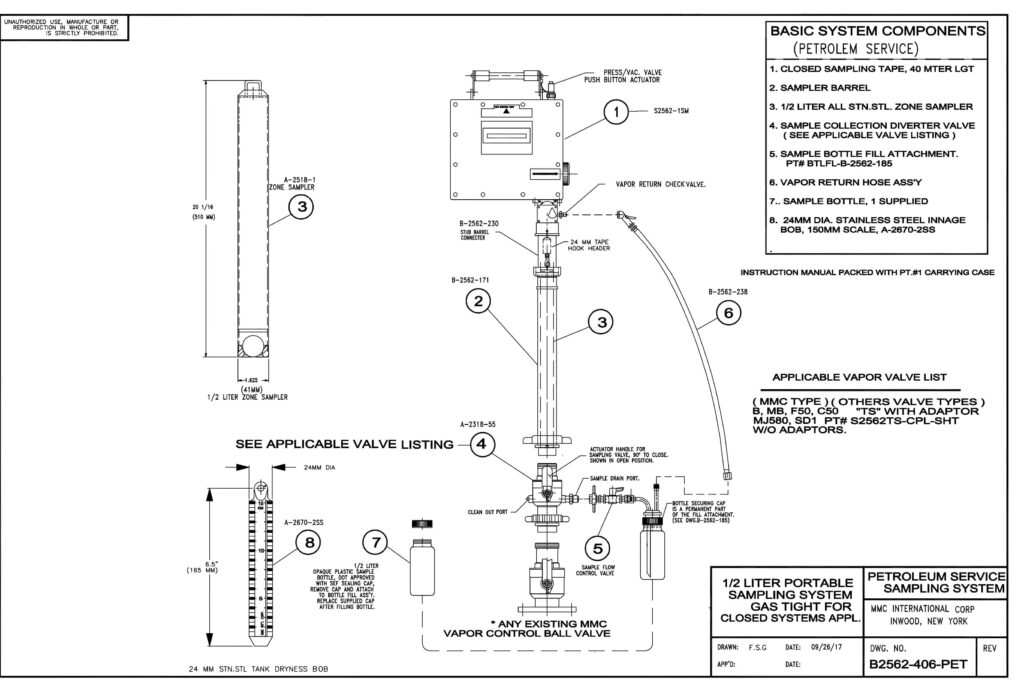

MMC’s Flexi-Dip Tank Sampling System is available in two varieties: the Fixed-In-Place (FIP) version designed for use with MMC’s unique S series vapor control valves with built-in sampling ports, and the Portable-In-Place (PIP) version designed for use with any standard MMC vapor control valve. Both Flexi-Dip systems are made entirely in the USA by MMC.

Fixed-In-Place (FIP) Version

The Flexi-Dip Fixed-In-Place (FIP) sampling system, valve, and “closed” sampling tape is a unique MMC Model MBS Fixed-In-Place vapor-control valve with a built-in sampling port. The S series of valves, including the BS and MBS, are simple to install, easy to maintain, and convenient to use. The valves and Flex-Dip FIP system will support the collection of 1/2- and 1/3-liter samples. (2″ Model MBS and BS valves for 1/2-liter sampler).

The FIP system, valve, and sampling tape is a gas-tight system. When it is closed and the tape is attached to any S series valve, it can extract and bottle a sample in place without exposing the sample to the atmosphere. The sample bottle twists off easily for capping, labeling, and transportation to the lab. Designed to meet or exceed all existing vapor-control regulations, the system is completely gas-tight. It employs a unique vapor return hose assembly which directs the sample bottle’s vapors back to the tape housing to maintain the system’s gas-tight integrity.

The Flexi-Dip FIP sampling system also includes a sturdy, molded plastic carrying case for convenient transportation and safe storage. Laboratory-grade, unbreakable sampling bottles are also available, along with a convenient sample bottle included with each system.

Portable-In-Place (PIP) Self-Contained Version

The Flexi-Dip Portable-In-Place (PIP) sampling system is designed for use with a wide range of standard MMC vapor-control valves, such as the B and MB units.

In parallel with the FIP version, the PIP sampling system is gas-tight and designed to meet or exceed all existing vapor-control regulations. The system also features a unique vapor return hose assembly which routes the sample bottle’s vapors back to the tape housing to maintain the system’s gas-tight integrity. Laboratory-grade, unbreakable sampling bottles are also available, along with a convenient sample bottle included with each system.

Please note:

- For the FIP system, valves and sampling tapes are ordered separately

- FIP and PIP systems include either a 1/2- or a 1/3-liter zone sampler device

- Closed-sampling gauging tapes are available in standard lengths of 100 feet or 40 meters

Closed Gas Tight Sampler

The MMC Gauging Sampling system is part of a growing family of MMC products designed to make the gauging and sampling of bulk petroleum and chemical products, more accurate and

safer. The easy use and safety in utilization of MMC Product equipment is always foremost in the minds of our designers.

The use of MMC Restricted Gauging and Sampling Equipment, in conjunction with MMC

Vapor Control Valves is well known and established worldwide.

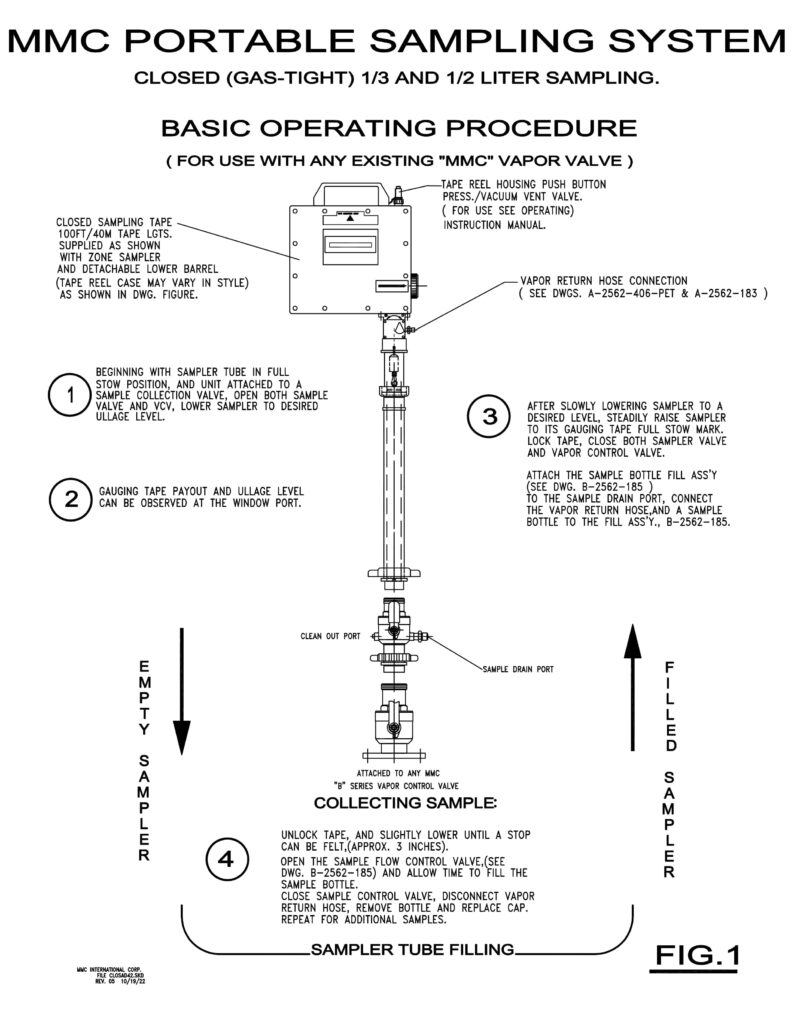

Basic Operating Procedures

This operation requires the use of MMC’s sampler tape and a suitable sampler container.

As far as cargo sampling, the sampler tape barrel is inserted into the vapor valve, and the

securing collar tightened. The vapor valve can now be opened, and the sample container lowered into the product.

A product sample is being taken into the sample cylinder as it is lowered into the desired sample level. Upon obtaining the desired sample level, the cylinder is raised with a continuous motion up into the sampler tape barrel, the valve is then closed.

The sampler tape can now be removed from the station. Carefully lower the sample container from the barrel and disconnect from the sampler hook. The contents of the sample container may now be poured into a suitable transfer container.

| Specifications: | |

|

Display Readable Temperature Range *Reading Limit Due to 3-1/3 Digit LCD Display on °F Range |

°F = -40° to 199.9°* °C = -40° to 150.0° |

| Guaranteed Temperature Calibration Range |

32°F to 190°F (0°C to 88°C) |

| Accuracy Over Calibration Range | ±0.2°F (±0.1°C) |

| Accuracy Linear Measurements | ±1/8” (±2.0 mm), Plus ±0.1% of Total Tape Length, worst case |

| Minimum Detectable Tank Bottom Liquid Level | 3/8” (10mm) |

| Minimum Detectable Floating Product Level | 1/8” (3mm) |

| Batteries for Intrinsically Safe Operation Only (Supplied) | Duracell MN1604 |

| Battery Drain (Temperature Mode) |

1.3 ma (In Air) 2.6 ma (In Fluid) |

| Display |

3-1/2″ Digit Liquid Crystal Display 1/2” Character Height |

| Operating Temperature Limit of Liquid Crystal Display |

-40°F to 176°F -40°C to 80° |

| Storage Temperature Limits |

-67°F to 185°F -55°C to 85°C |

| Available Tape Length, *Single Face Scales |

50 ft (15 m) 65 ft (20 m) 75 ft (25 m) 100 ft (30 m) *100 ft (10ths & 100ths) 35m |

| Hazardous Environments |

Certified Intrinsically Safe BASEEFA/SIRA, |

Flexi-dip Sampling Tape

The following instructions apply to the Flexidip Portable Gauging Tape Type D-2401-2** covered by certificate number BAS 02ATEX1274X. The information contained herein shall be included with every batch of products old, either as a separate sheet or incorporated as a discrete section in an instruction manual.

Warning: use only duracell/procell mn1604 battery replacement.

Do not replace battery were an explosive gas atmosphere may be present.

Be aware of potential electrostatic charging hazard after loading distilled

Petroleum.

This device must be grounded.

Instructions for safe selection, installation, use, maintenance and repair:

- The equipment may be used in zones 0, 1, or 2 with flammable gases.

- The equipment may be used in the presence of flammable gases and vapours with apparatus groups IIC or IIB or IIA and with temperature classes T1 or T2 or T3 or T4.

- The equipment is certified for use in ambient temperatures in the range of –20°C to +40°C and should not be used outside this range.

- The equipment is to be installed by suitably trained personnel in accordance with the applicable code of practice (typically IEC EN 60079-14)

- The equipment does not require assembly or dismantling.

- With regard to safety it is not necessary to check for correct operation.

- No user adjustment is required.

- Regular periodic inspection of the equipment should be performed by suitably trained personnel in accordance with the applicable code of practice to ensure it is maintained in a satisfactory condition.

- The equipment is not intended to be repaired by the user. Repair of the equipment is to be carried out by the manufacturer, or their approved agents, in accordance with the applicable code of practice.

- The equipment contains no other customer-replaceable parts.

- Under certain extreme circumstances, the non-metallic parts incorporated in the enclosure of this equipment may generate an ignition-capable level of electrostatic charge. Therefore, particularly in the event of an installation in zone 0, the equipment shall not be installed in a location where the external conditions are conducive to the build-up of electrostatic charge on such surfaces. Additionally the equipment shall only be cleaned with a damp cloth.

- If the equipment is likely to come into contact with aggressive substances, e.g. acidic liquids or gases that may attack metals or solvents that may affect polymeric materials, then it is the responsibility of the user to take suitable precautions that prevent it from being adversely affected thus ensuring that the type of protection is not compromised.

Introduction

The MMC Closed Gauging Sampling system is part of a growing family of MMC products designed to make the gauging and sampling of bulk petroleum and chemical products, more accurate and safer.

The easy use and safety in utilization of MMC Product equipment is always foremost in the minds of our designers.

The use of MMC Restricted Gauging and Sampling Equipment, in conjunction with MMC Vapor Control Valves is well known and established worldwide.

In keeping with a growing demand and in some cases prescribed legislation, MMC developed a Closed Hand Gauging System, which has the same gauging feature as its Restricted Hand Gauging Equipment.

The Closed Hand Gauging System, as does the Restricted Gauging System, allows an operator to determine cargo Ullage, Interface, and Temperature.

In addition, and as prime objective of the system design, operator exposure to product vapors is virtually eliminated.

As a natural next step in the development of equipment for use in Closed Applications, MMC has also developed the Closed Portable Sampling System. Information on the Closed Portable Sampling System is available upon request.

System Overview

MMC’s Portable Closed Sampling System and its sample collections valve, operate in conjunction with but independently of a cargo tank’s existing vapor control valve. Once the system is attached to any MMC vapor control valve, an operator can extract and bottle a product sample in place, without transfer of the collected sample to another container.

In addition, and as prime objective of the system design, operator exposure to product vapors, and the traditional physical handling of the collected products, has been greatly reduced.

The system is gas tight and has been designed to meet or exceed the current vapor control regulations.

To achieve the above design goals, the system uses a unique combination of vapor return hose assembly, sample collection valve and sample bottle fill attachment.

System operation is simple, easily understood, and not complicated using laboratory type accessories.

The entire system is made in the U.S.A.

General Guide To Chemical Resistance Of Supplied Sample Bottles:

Material: (Bottle And Cap) Florinated High Density Polyethylene

Maximum temperature: +120° C TO -100° C

Color: Translucent

Meets the U.S. Department of Transportation, DOT-2E requirements for packaging and transportation of hazardous materials. (See also caution Notice Section 2.6.1 of the instruction manual).

| Chemical Class | Rating |

|---|---|

| Acids, Dilute or Weak | Excellent |

| Acids, Strong and Concentrated | Excellent |

| Aliphatic Alcohol | Excellent |

| Aldehydes | Good |

| Bases | Excellent |

| Esters | Excellent |

| Hydrocarbons, Aliphatic | Excellent |

| Hydrocarbons, Aromatic | Excellent |

| Hydrocarbons, Halogenated | Good |

| Ketones | Excellent |

| Strong Oxidizers | Fair |

The above guide is provided solely as general overview of chemical compatibility. Compatibility with specific chemicals should be further investigated before usage.

MMC does not make or claim suitability of the supplied sample bottles as being approved for sampling usage by any specific regulatory body, or in meeting the requirements of any industry or testing society standard.

Replacement Parts List

| Item | Description | Part Number |

|---|---|---|

| 1 | Sampling Tape 100ft/40m With Snaphook | TAP40M(100FT)-W-HOOK-C |

| 2 | 1/3 Liter Zone Sampler, Stainless Steel | A-2518-3-1/3 LTR |

| 3 | ½ Liter Zone Sampler Stainless Steel | A-2518-1-1/2-LTR |

| 4 | Primary View Assembly | DWG. A-2562-146-SG-PRIM* |

| 5 | Wiper Assembly Complete | B-2562-26-WPR-ASSY |

| 6 | Wiper Assembly Gasket (Buna-N) | A-2562-90-WPR-GSKT |

| 7 | Gasket, Reel Housing Cover (Buna-N) | B-2562-322-BN-SML |

| 8 | Cover Screws, “O” Ring Sealed | SCR-10-32X-5/8-SLOT-PH |

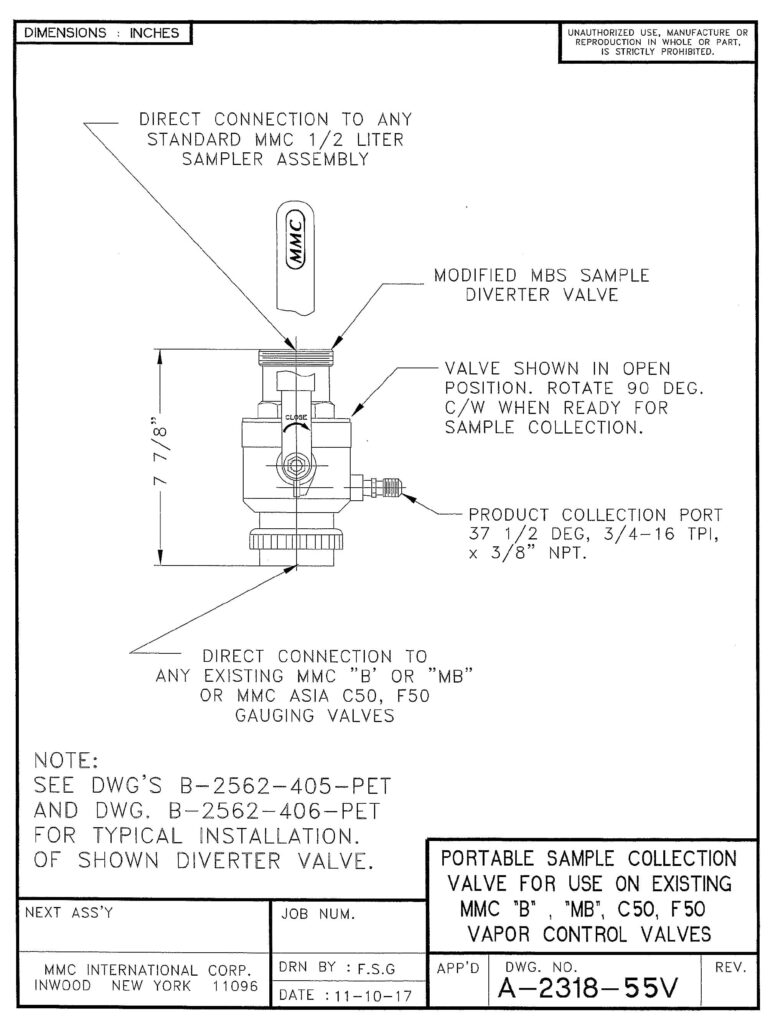

| 9 | Sample Collection Valve | A-2518-55V |

| 10 | Grounding Cable Assembly | B-2562-72A |

| 11 | ½ Filling Attachment Assembly | DWG. B-2562-185-BTL-FL* |

| 12 | Push Button Actuator, Nylon | A-2562-134 |

| 13 | “O” Ring, Stub Barrel Coupling End | O/R2 134V |

*Order by Drawing Part Number, included in this manual.