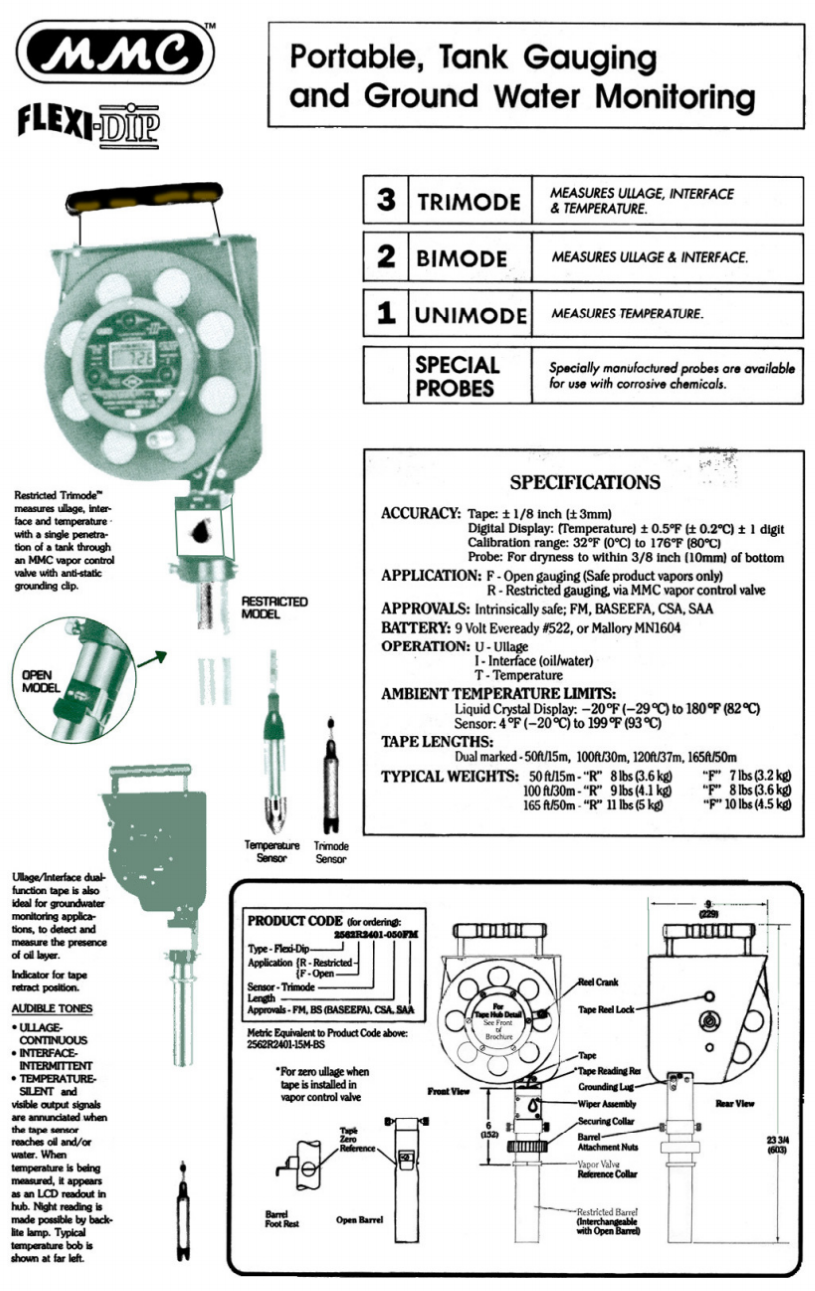

MMC SONIC TAPE GAUGING DEVICE

MMC Closed Type Gas Tight TRIMODE UTI Gauging Tape

Description

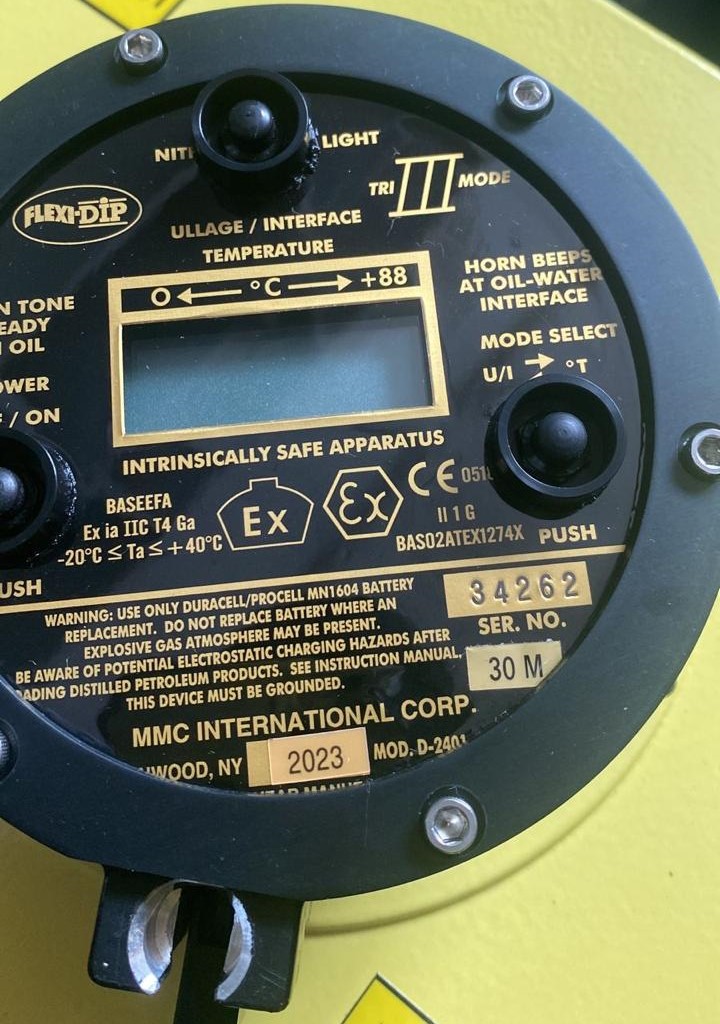

The Closed Flexi-Dip™ (also known as a Universal Tank Interface or UTI Meter) is a battery-operated, intrinsically safe measurement device designed for use with vapor control valves on storage or cargo tanks. This device enables precise and secure closed-system gauging, effectively sealing the system to prevent the release of toxic vapors during cargo handling. The measuring tape is available in both Metric and English units, with an anti-static coating on both the tape and sensor to ensure safe operation.

The MMC Closed Type Gas Tight TRIMODE UTI Gauging Device is a versatile, high-precision instrument designed for marine applications, catering to the needs of professionals who require reliable cargo tank monitoring equipment and portable tank level measurement devices. Known for its integration with the MMC UTI Tape and MMC Sonic Tape models, this device supports triple-function gauging for temperature ullage interface and provides accurate measurements in various tank environments. Equipped with MMC vapor locks and gas-tight sealing, this cargo tank gauging instrument ensures safety and compliance, preventing vapor leaks during operation. With its oil-water interface detector, it offers precise liquid level detection, making it a go-to device for marine suppliers of MMC and sampling equipment sellers. Popular in regions like Asia and Japan, the TRIMODE UTI device is available through MMC Sonic Tape Dealers and can be found under models such as the MMC Tape Model D2401.

Key Features

Closed Gauging System: Once inserted into the vapor control valve, the system remains closed, maintaining a seal and complying with global regulatory standards as a fixed gauging equivalent for the duration of cargo operations.

User-Friendly Tape Design: The tape includes markings to indicate direction, motion, and full rewind position, facilitating ease of use and accuracy in fluid level measurement.

Grounding Safety: Comes with a coiled grounding cable and a large alligator clip for safe grounding as standard equipment.

Specification

| Display Readable Temperature Range

*Reading Limit Due to 3-1/3 Digit LCD Display on °F Range |

°F = -40° to 199.9°* °C = -40° to 150.0° |

| Guaranteed Temperature Calibration Range (0°C to 88°C) | 32°F to 190°F |

| Accuracy Over Calibration Range | ±0.5°F (±0.2°C) |

| Accuracy Linear Measurements | ±1/8” (±2.0 MM), Plus ±0.1% of Total Tape Length, worst case |

| Minimum Detectable Tank Bottom Liquid Level | 3/8” (10MM) |

| Minimum Detectable Floating Product Level | 1/8” (3MM) |

| Batteries for Intrinsically Safe Operation Only Duracell MN1604 (supplied) | Duracell MN1604 |

| Battery Drain (Temperature Mode) | 1.3 ma (In Air) 2.6 ma (In Fluid)/td> |

| Display | 3-1/2 Digit Liquid Crystal Display 1/2” Character Height |

| Operating Temperature Limit of Liquid Crystal Display, | -40°F to 176°F -40°C to 80° |

| Storage Temperature Limits | -67°F to 185°F -55°C to 85°C |

| Available Tape Length, *Single Face Scales | 50 FT (15 Meters) 65 FT (20 Meters) 75 FT (25 Meters) 100 FT (30 Meters) *100 FT (10ths & 100ths) 35M, 40M |

| Hazardous Environments | Certified Intrinsically Safe BASEEFA/SIRA, Gas Groups C & D |

MMC Portable Electronic Gauging Tape Standard Production Linear Measurement Accuracy

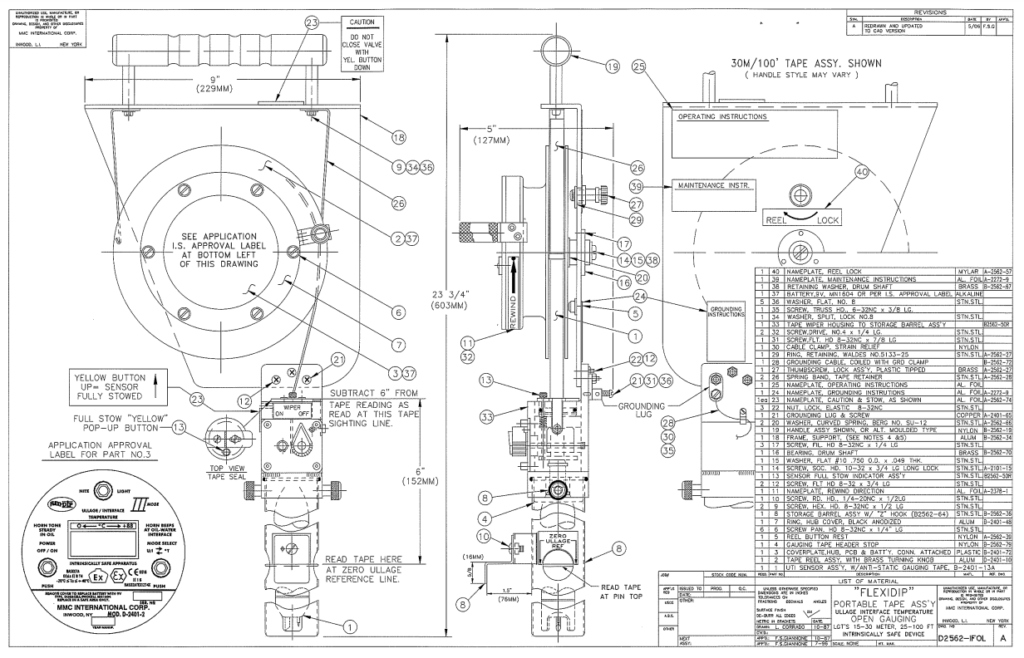

| Applicable Equipment | MMC Models D-2401-2 (Trimode), D-2401-2UI (Ullage/Interface) |

| Tape Lengths: | 50FT., 65FT., 75FT., 100FT. and 15M, 20M, 25M, 30M, 35M, 40M. |

| Basic Gauging Tape Style: | Steel, 0.375 wide x 0.006 thick, yellow or white faced, black & red graduation markings. Manufactured in accordance with API Chapter MPMS 3.1A industrial guideline. |

| System Linear Accuracy: | English Reading, ±1/8″ of reading Metric Reading, ±2MM of reading plus +/- 0.01% of total tape length |

General Statement Of Linear Accuracy

MMC guarantees that the listed, newly produced equipment models, including the specified gauging tape styles and lengths, will meet the stated system accuracy requirements. Certification of accuracy for new equipment is available at an additional cost, and customized quotes can be provided for certification to accuracy standards beyond the stated system accuracy.

The Portable Tank Level Measurement Device with Temperature Ullage Interface functionality is an essential tool for accurately gauging fluid levels and temperatures in storage and cargo tanks. Designed for flexibility and ease of transport, this device enables precise measurements in various tank environments, supporting essential tasks in the marine and industrial sectors.

Parts

MMC Sonic Tape

MMC vapor locks

MMC Sensor Winh Barrel

Special Features

- Conductive Tape Surface to Drain Off any Static Charge

- Grounding Cable with Heavy Alligator Clamp

- Dual-Purpose Spring-Loaded Tape Crank and Tape Position Lock

- Watertight Electronics Construction with Sealed Switches

- All Stainless-Steel Fasteners

- Nylon Coated Aluminum Reel Housing for Lightweight Portability

- Low Battery Display Indicator

- High Daylight Visibility with Liquid Crystal Display

- Push-Button Night Light

- Rapid Multiple Temperature Measurements

- Easily Renewable Tape Wiper

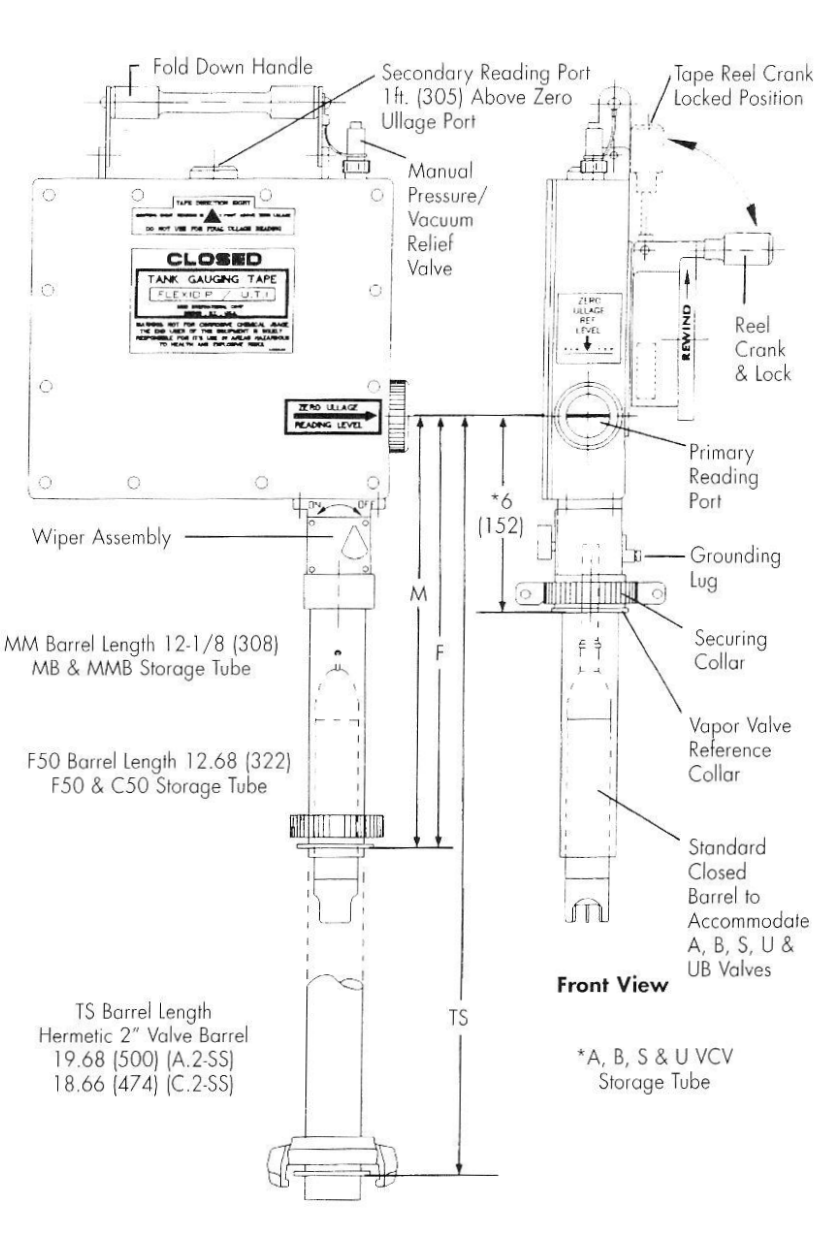

- Manually Operated Vacuum/Pressure Relief Valve

- Primary and Secondary Tape Sight Glasses

- Anti-Wind Internal Spring-Loaded Stop Lever Sensor

- Internal Tape/Reel Confinement Springs

- Gas Tight Construction

Restricted Type MMC USA Utimeter Gauging Tape