Home / MMC Restricted – Open Type UTI

MMC Restricted – Open Type UTI

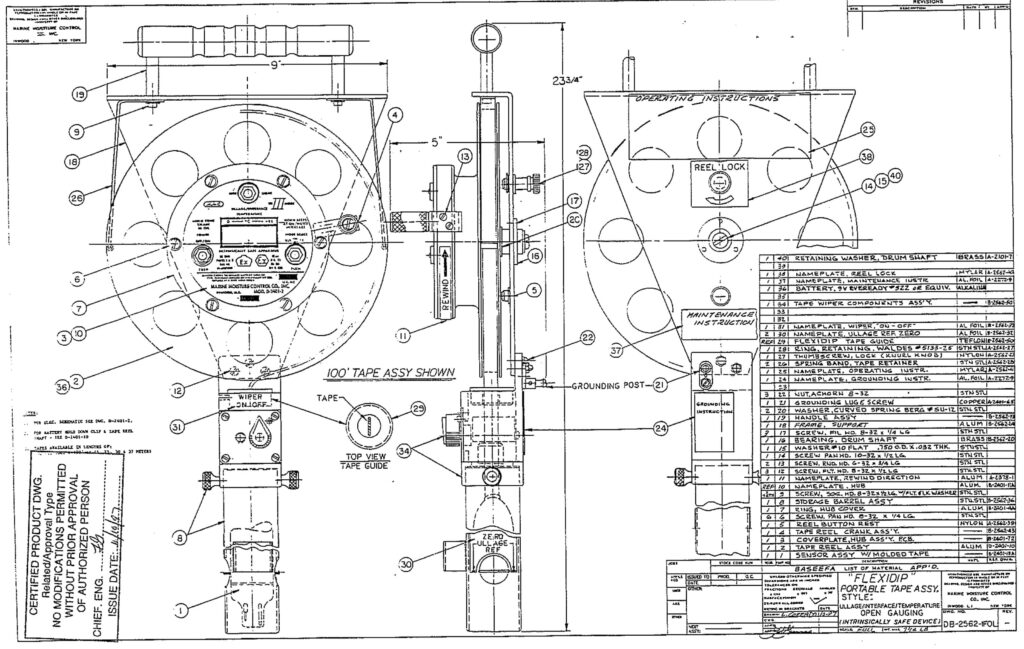

MMC, a world-leading manufacturer, produces Portable Electronic Gauging Tapes for shipboard and land-based petroleum and chemical tanks. These intrinsically safe battery-operated units, such as the Portable Closed Flexi-Dip tape, create sealed gauging systems that prevent toxic vapors from escaping during tank measurement. The tape features metric or imperial markings, anti-static coating, color-coded design for easy use, and a coiled grounding cable. It’s recognized globally as equivalent to fixed gauging systems when securely installed in the valve during tank loading or unloading.

The accuracy of these gauging tapes is impressive, with tape readings at +/- 1/8″ and temperature displays with minimal error. They operate within ambient temperature limits of -20°F to 120°F and product temperature limits of -20°C to +40°C. Powered by a 9-Volt Duracell MN1604 battery, these tapes come in various lengths and are built to withstand pressure limits of 3 psi working and 7.5 psi maximum. Certified as intrinsically safe by BASEEFA and CSA, MMC Portable Electronic Gauging Tapes offer reliability and precision in measuring ullage, oil-water interfaces, temperature, and bottom dryness in tank systems, ensuring safety and compliance in the petroleum and chemical industries.

MMC PORTABLE ELECTRONIC GAUGING TAPE STANDARD PRODUCTION LINEAR MEASUREMENT ACCURACY

| Applicable Equipment | MMC Models D-2401-2 (Trimode), D-2401-2UI (Ullage/Interface |

| Tape Lengths | 50 FT.,65FT., 75 FT., 100 FT, and 15M, 20M, 25M, 30M ,40M |

| Basic Gauging Tape Style | Steel, 0.375 wide x 0.006 thick, yellow or white faced, black and red graduation markings. Manufactured in accordance with Federal Specification GGG-T-106F. |

| System Linear Accuracy at 68°F | English Reading, ±1/8″ of reading plus ± 0.01% of total tape length. Metric Reading, ±2MM of reading plus +/- 0.01% of total tape length. |

| Battery | 9-Volt Duracell MN1604. |

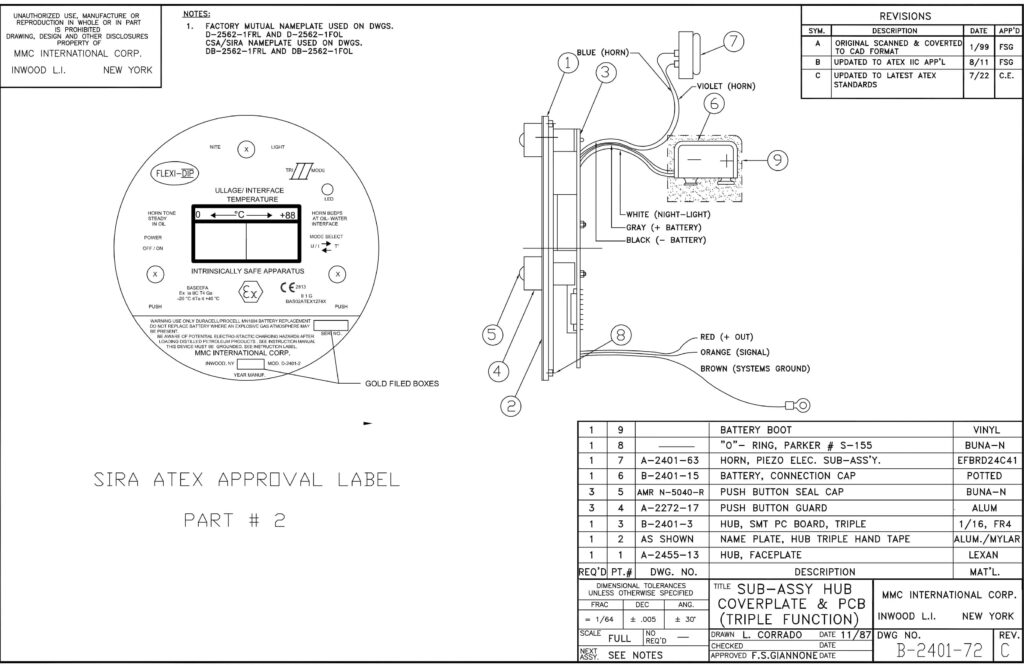

WARNING: USE ONLY DURACELL/PROCELL MN1604 BATTERY REPLACEMENT.

- Do Not Replace Battery Were an Explosive Gas Atmosphere May Be Present.

- Be Aware of Potential Electrostatic Charging Hazard After Loading Distilled Petroleum.

- This Device Must Be Grounded.

Instructions for safe selection, installation, use, maintenance and repair

Safety Instructions for Device Use in Explosive Atmospheres:

Battery Replacement: Avoid replacing the battery in environments with potential explosive gas atmospheres.

Electrostatic Charging Hazard: Be cautious of electrostatic charge risks after loading distilled petroleum.

Grounding Requirement: Ensure this device is grounded.

Guidelines for Safe Selection, Installation, Use, Maintenance, and Repair:

Applicable Zones: The device is suitable for use in zones 0, 1, or 2 with flammable gases.

Flammable Gases and Vapours Compatibility: Compatible with apparatus groups IIC, IIB, and IIA and temperature classes T1 to T4.

Temperature Range: Operate the device only within ambient temperatures of –20°C to +40°C.

Qualified Installation: Installation should be performed by trained personnel following IEC EN 60079-14 or relevant code of practice.

Assembly Requirements: No assembly or dismantling is required for operation.

Safety Checks: Routine safety checks for operational accuracy are not required.

User Adjustments: The device requires no user adjustments.

Periodic Inspection: Regular inspections should be conducted by qualified personnel to maintain safe conditions.

Repair Policy: Repairs should be carried out solely by the manufacturer or approved agents, following applicable codes.

User-Serviceable Parts: The device has no other parts replaceable by the user.

Electrostatic Charge Precaution:

In installations within zone 0, avoid areas prone to electrostatic charge buildup on non-metallic surfaces.

Clean the device only with a damp cloth to avoid electrostatic buildup.

Chemical Exposure: If exposed to aggressive substances (e.g., acids, gases, or solvents), the user must ensure protection to avoid compromising device safety.

Linear Accuracy Specifications

MMC Portable Electronic Gauging Tape Standard Production Linear Measurement Accuracy

| Applicable Equipment | MMC Models D-2401-2 (Trimode), D-2401-2UI (Ullage/Interface) |

| Tape Lengths | 50 FT.,65FT., 75 FT., 100 FT, and 15M, 20M, 25M, 30M ,40M |

| Basic Gauging Tape Style | Steel, 0.375 wide x 0.006 thick, yellow or white faced, black and red graduation markings. Manufactured in accordance with Federal Specification GGG-T-106F. |

| System Linear Accuracy at 68°F | English Reading, ±1/8″ of reading plus ± 0.01% of total tape length. Metric Reading, ±2MM of reading plus +/- 0.01% of total tape length. |

Linear Accuracy Specifications

Intrinsically Safe Triple Function Gauging Tape

General

| Specifications | |

|---|---|

| Display Readable Temperature Range | °F = -40° to 199.9°* |

| *Reading Limit Due to 3-1/3 Digit LCD Display on °F Range | °C = -40° to 150.0° |

| Guaranteed Temperature Calibration Range | 32°F to 190°F (0°C to 88°C) |

| Accuracy Over Calibration Range | ±0.5°F (±0.2°C) |

| Accuracy Linear Measurements | ±1/8” (±2.0 MM), Plus ±0.1% of Total Tape Length, worst case |

| Minimum Detectable Tank Bottom Liquid Level | 3/8” (10MM) |

| Minimum Detectable Floating Product Level | 1/8” (3MM) |

| Batteries for Intrinsically Safe Operation Only | Duracell MN1604 (supplied) |

| Battery Drain (Temperature Mode) | 1.3 ma (In Air)

2.6 ma (In Fluid) |

| Display | 3-1/2 Digit Liquid Crystal Display 1/2” Character Height |

| Operating Temperature Limit of Liquid Crystal Display | -40°F to 176°F

-40°C to 80° |

| Storage Temperature Limits | -67°F to 185°F

-55°C to 85°C |

| Available Tape Length | 50 FT (15 Meters) 65 FT (20 Meters) 75 FT (25 Meters) 100 FT (30 Meters) 100 FT (10ths & 100ths) 40M |

| Hazardous Environments | Certified Intrinsically Safe BASEEFA/SIRA, Gas Groups C & D |

General Statement Of Linear Accuracy

MMC warrants that the above listed, newly produced equipment models, incorporating the listed basic gauging tape style and lengths, will perform to the stated system accuracy.

Certification of accuracy for new equipment is available at an extra cost. Certification costs to standards of accuracy more precise than the stated system accuracy will be quoted upon request.

Special Features

- Conductive Tape Surface to Drain Off any Static Charge

- Grounding Cable with Heavy Alligator Clamp

- Watertight Electronics Construction with Sealed Switches

- All Stainless-Steel Fasteners

- Low Battery Display Indicator

- Nylon Coated Aluminum Reel Housing for Lightweight Portability

- High Daylight Visibility with Liquid Crystal Display

- Push-Button Night Light

- Rapid Multiple Temperature Measurements

- IMO Approved for Oil/Water Interface Detection

- Full Stow “Pop-up” Button Spring-Loaded Tape Wiper Housing Gas Seal

List Of Chemicals

The following list of chemicals, although not all-inclusive, are known to attack PES, the material from which a portion of the sonic liquid level sensor is made.

Prolonged submergence of the sensor should be avoided.

After submergence in any of these chemicals, a thorough cleaning of the sensor head should be conducted to prolong sensor life.

- * Acetaldehyde – CH3CHO

- * Acetone – CH3CHOH3

- * Aniline – C6H5CL

- Benzaldehyde – C6H5CL

- Chlorobenzene – C6H5CL

- Cresol – CH3C6H4OH

- * Cyclohexanone – C6H10O

- Dichlorobenzene – C6H4CL2

- 1,2 Dichlorethane – CH2CLCH2CL

- * Ethyl Acetate – CH3COOC2H5

- * Ethylene Glycol – HOC3H4OH

- * Methyl Ethyl Ketone – C2H5COCH3

- * Methylene Chloride – CH2CL2

- Nitro Benzene – C6H5NO2

- * Phenol – C6H5OH

- * Pyrdine – C5H5OH

- Toluene – C6H5CH2

- Tricloroethylene – CLCH:CCL2

*These chemicals are known to be water soluble, ranging from very to slightly; while this information is useful in sensor cleaning procedure, it will also make interface readings less accurate. In such case, good interface readings will depend upon the relative specific gravities involved. In the extreme case of dissolved water within a cargo, and upon ullage gauging of these chemicals, a beeping tone will be heard instead of the normal steady horn tone. This sensor response should not be interpreted as a malfunctioning unit.